If you are on the lookout for a new forklift to meet your material handling needs, there is one question that you will inevitably encounter: LPG or Battery Electric?

To resolve this issue we will weigh up the financial and environmental costs associated with this decision. We will also determine significant points that you will need to take into consideration when purchasing a Battery Electric or LPG forklift.

A little History…

• Batteries have been in use in a materials handling context for at least 200 years. The most common battery used in the materials handling industry, currently, is the lead acid battery, whose original form was patented by French physicist Gaston Planté in 1859.

• The first ever Internal Combustion Engine (ICE) can be traced back to Dutch polymath Christiaan Huygens’ experiments in 1673, where he used gunpowder to drive water pumps to supply water to the Versailles palace gardens.

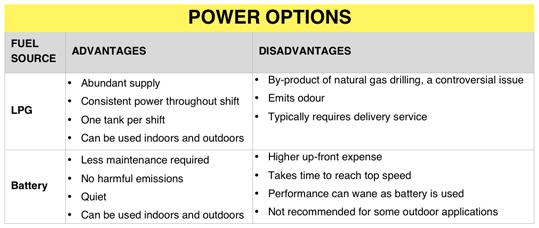

Performance – some pros and cons:

The above table illustrates the main pros and cons of each power source. The LPG forklifts main advantage over Battery Electric forklifts is their ability to provide consistently strong power. Batteries can be slower to accelerate and lift and also travel slower than their LPG counterparts. Whilst LPG forklifts are stronger, Battery Electric forklifts have a significantly lower noise output. Battery models have fewer moving parts and no exhaust or engine noise, producing only one quarter of the noise of LPG forklifts.

Cost Comparison

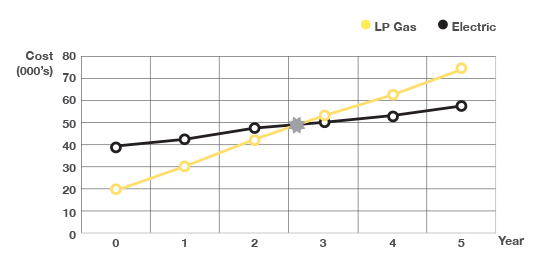

In terms of initial cost LPG forklifts are significantly less expensive than electric forklifts. After this however, the key costs are found in fuel and maintenance. It is here, that the benefits of battery electrics are most keenly felt.

The graph below, provided by NACCO, shows the total cost of ownership for electric vs. ICE lift trucks, including the cost of two batteries and one charger at year zero. Over five years, an electric truck saves more than 8 per cent in total costs.

The initial cost of for an electric forklift can be double the price of its ICE equivalent, although it is important to take into consideration the total cost of ownership upon your purchase.

Environmental Impact:

When the working environment is considered, electric trucks can easily be seen as superior to ICE models. As electric models do not emit any exhausts, indoor air quality is greatly improved. Depending on your application, this can make a big difference:

Take a food distribution centre for example. An internal combustion engines exhaust might be deemed unacceptable, or harmful to your product. The lack of exhaust fumes ensure the integrity of your product as indoor air quality is improved by eliminating all exhaust. Money is also saved on elaborate and expensive HVAC systems that can use a lot of power. Furthermore, your employees are not adversely affected by poor quality air inside the facility.

Although, it is important to factor in that batteries still require electricity from the grid and are far from perfect in terms of green house gas emissions.

Internal combustion engines (diesel and LPG) regularly require servicing and a top up of consumables such as engine oil, transmission and radiator fluids and filters – parts that are both considerable financially and which can be very harmful to the environment if not disposed of properly.

Conclusion? Application! Application! Application!

The most important aspect of choosing the right forklift for your operation is to consider your application and its needs. Food distributions centres are strongly encouraged by OHS standards, but not obliged, to operate with battery electrics. On the other hand, for big trucks, the only viable option on the market is diesel power.

If you’re looking at operating and managing a large fleet, then economies of scale will definitely lower battery charging and maintenance cost. The same however, can be said for LPG supply. In a small to medium warehouse scenario operating in narrow aisles, you may desire a battery electric forklift in order to minimise exhaust fumes. However, if your forklift will be required both in and outdoors on a regular basis, then perhaps an ICE truck will be more suited to the varied weather conditions. As you can see, there are many different elements to consider. The decision will thus depend on the specifics of your site and your intended applications.

Source: https://www.aalhysterforklifts.com.au/index.php/about/blog-post/lpg_vs._electric_forklifts